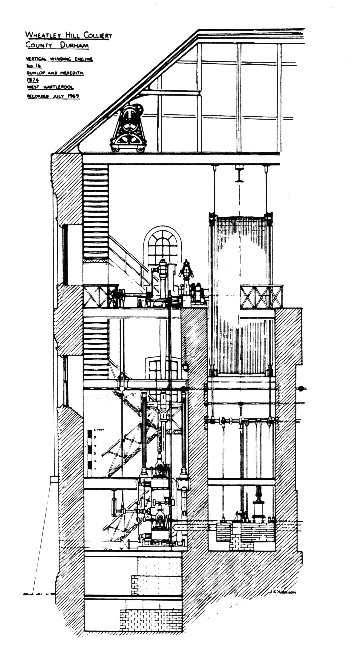

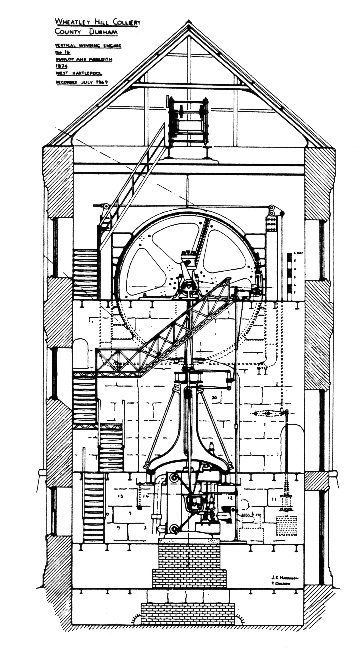

Two Durham Colliery Vertical Winding Engines

by John K. Harrison(1970)

Wheatley Hill Colliery. Map Ref: NZ 385393

Since the recording of the Beamish No. 2 Pit vertical winding engine, the last of the big Crowther engines in County Durham, we have had another last (or near last?) in the area., with the passing from working life of the Wheatley Hill vertical winding engine originally built in 1874, by Messrs. Dunlop & Meredith of West Hartlepool.

This engine offers some interesting contrasts with the earlier Beamish engine. Firstly, it is bigger by far and is a double, and secondly, unlike the older engine it has suffered many modifications. In spite of this the overall pattern is still clear and if the reader will cross check with the drawings we can build up a picture of its development to its final form.

Little is known about the firm of Messrs. Dunlop & Meredith except that it did exist and that old drawings state that they made the engine. The facilities of the firm must have been fairly extensive for them to be able to undertake this major piece of construction. The engine was evidently erected elsewhere from the present site and was bought by the Hartlepool Coal Company? secondhand. For many years it stood in the colliery yard and was finally re-erected at Wheatley Hill in 1900. This explains the first mystery - an 1874 vintage engine inside an engine house dated 1900, and clearly of the architecture of that period. The stone piers upon which the engine stands are part of the original engine and have been carefully numbered and removed to the present site with the iron work. One of the stones is placed upside down in the new house and the stone work does not quite fill the full depth of the house. The older house was obviously more cramped.

The engine as re-erected was in its original form. For many years it was unpainted and was simply rubbed down with engine oil, the green paint and lining being of National Coal Board vintage. The drum was made up of three cast iron spoked wheels, the centre one slightly larger in diameter than the outer ones to give a pronounced crown to the drum. The wooden spars were in two parts to make this possible. This drum had two band brakes both with upper and lower bands. These bands were plain steel ones and ran on wooden cleats bolted to the drum. Before this drum finally became unsafe and was scrapped the upper brake bands had been removed and the engine was braked by the lower bands only and by steam in the cylinders. This was a highly unsatisfactory arrangement.

In 1929 the old Lancashire boilers working at 60 lbs. p.s. i., were removed and replaced by Babcock & Wilcox tube boilers working at 150 lbs. p.s.i., superheated steam. Such a radical adjustment in steam pressure had to be accommodated in the engine and the old cylinders (probably 36" x 6'0" stroke) were taken out and replaced by new ones at 30" x 6’0" stroke. At the same time the new valve gear was put in. This work was carried out by Messrs. Bradley & Craven of Wakefield.

In 1938/39 the old drum was removed and probably only just in time since during its dismantling most of the spokes were found to be cracked. A new steel drum was put in by Messrs. Worsley Mesnes of Wigan and they sub-contracted for the new Whitmore type caliper brakes to Messrs. Coulsons of Spennymoor.

On several occasions the base iron castings for the cylinders gave trouble by cracking and they had to be replaced eventually by steel castings. On one occasion on trying to lift the cylinder for such a replacement the hand windlass on the service beams suddenly collapsed and it was found that one cylinder nut had not been undone. One more part of the original engine disappeared.'

We can see from this that the original parts on the engine which remained to the end of its life were the main crank shaft, cranks and bearings, the connecting rod and piston rod, the crosshead, the guides, the "spectacles", and the cast iron beams supporting the guides. Around these were later additions: the fine red and white brick steel beamed engine house built by the colliery mason, the drum and caliper brakes and the complicated braking and steam control mechanisms. The latter deserve some mention at this stage. The governor operated cut offs on the valves. On days when the steam was "bad" the governor could be disengaged from this duty by a quick "flick" of the reversing gear which threw a link out over the side of the governor until the engine was once again reversed. The reversing gear was operated by a steam donkey (60 lbs. p.s. i.) which was on the right hand engine (and not shown) and had a rod passing through the walls to the left hand engine.

The brakes were normally in the "on" position, and were held on very firmly by heavy weights suspended on one end of the brake lever arm and by a compression spring at the other (not shown). They were taken off by a second pneumatically controlled donkey (150 lbs. p.s.i.) A steam cylinder between the two stone piers, connected directly to the main steam junction for the engine cylinders, engaged the brakes if the main steam pressure fell below about 90 lbs. p.s.i., so that the engine would be stopped completely. Both the brake donkey and the reversing donkey were brought into duty by the "slow banker" gear which had two functions: (1) to prevent overwinding; (2) to prevent excessive speed of the cage in the shaft.

When the N. C. B. took over the colliery they instituted such ferocious braking tests that the main stone piers of the engine house were cracked and ties had to be put across the building. The engine in its final form performed its duties efficiently. It did all the heavy winding at the colliery in spite of the installation of a second engine - a horizontal Robey -and in the memory of the winding man, Mr. Charlie Daly, was never out of work except when servicing and repairs were carried out.

Attempts were made to preserve this engine by Mr. Frank Atkinson of the Bowes Museum, for the projected open-air museum at Beamish Park, but the removal of such a large piece of equipment would have been a major project in its own right, and proved to be beyond present means. The drawing's with this article never could be complete, as I am sure the reader will understand, but I offer them for the record. Finally I must acknowledge help given at various times with the drawings by boys of Eston Grammar School; my colleague, Mr. Peter Oberon; Miss Olivia Lambert; Mr. Nigel Chapman; and, particularly, the time given by Mr. Charlie Daly in telling the fascinating story of this engine.